From now, we need to finalize our foot sole design and then begin incorporating the elasticity function.

Friday, January 29, 2016

January 29, 2016

From now, we need to finalize our foot sole design and then begin incorporating the elasticity function.

Monday, January 25, 2016

January 25, 2016

Our bands have arrived and work well to secure the calf section. We are now making adjustments to the design of our foot sole section (in or outside of the shoe) and their respective hinges (one or two degrees of motion, attached on the outside instead of having the braces "sandwiched" between them). Then, we will work on the elasticity function.

We have extruded the pegs directly from the calf section so that the foot sole section can be attached directly which will exclude the second degree of motion which the hinge created. When thinking about ways to incorporate the elasticity function which will life the toes up, a possibility would be to use a rubber "string" that can we wrapped around the peg and tightened if needed. It will serve to lift the user's toes up with the strength they need.

Friday, January 22, 2016

Thursday, January 21, 2016

January 21, 2016

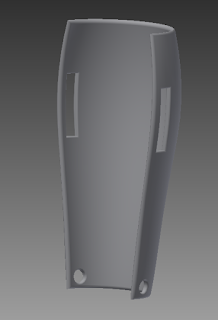

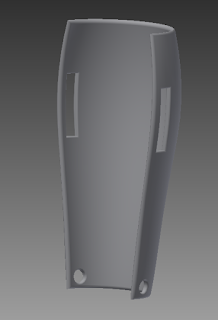

Today, we redesigned the hinges. They now have a thinner profile and and longer pegs. Also, instead of connecting completely together, the pegs will be inserted through the other side and will be secured with a rubber end cap. The CAD Model for the new design can be seen below.

*We still need to figure out how to design the elasticity adjuster to lift the user's toes up as well as a way to secure the bottom foot sole section to the shoe. (A possible idea is to use attachments on either side of the calf section and connected to both of these will be "strong rubber bands" with a Velcro band at the end for adjustment, attached to both, that can be secured around the shoe and foot sole section. This design, however, will require this brace to exist on the exterior. Other options are possible as well with further exploration.)

*We still need to figure out how to design the elasticity adjuster to lift the user's toes up as well as a way to secure the bottom foot sole section to the shoe. (A possible idea is to use attachments on either side of the calf section and connected to both of these will be "strong rubber bands" with a Velcro band at the end for adjustment, attached to both, that can be secured around the shoe and foot sole section. This design, however, will require this brace to exist on the exterior. Other options are possible as well with further exploration.)

We will order these rubber end caps which have an outer diameter of 11 mm or 0.4 inches. The outside "lip" will keep the attachments secure. The design can be adjusted to fit these caps if they need to be used in the final design.

Wednesday, January 20, 2016

January 20, 2016

One of the hinges was printed (see below). Adjustments that need to be made include a thinner profile as well as a slightly longer pegs that secure themselves together and also allow for movement. Either that or the legs on the foot sole section can be elongated and the holes of both parts can connect together with an attachment piece to secure them.

Tuesday, January 19, 2016

January 19, 2016

Update: Our hinge will be printed shortly, and the bands will be ordered. This will complete our next prototype. Also, we have emailed Mr. Nye to set up a second meeting with our City As Our Campus mentor, Dr. Matt Caster. A meeting with Donny from Union Orthotics & Prosthetics will hopefully be scheduled soon as well.

We will instead be ordering these 18 x 2 inch cinch straps: http://www.amazon.com/18-Inch-Cinch-Straps-Pack/dp/B00VETJKRU/ref=sr_1_6?ie=UTF8&qid=1453231200&sr=8-6&keywords=cinch+straps

We will instead be ordering these 18 x 2 inch cinch straps: http://www.amazon.com/18-Inch-Cinch-Straps-Pack/dp/B00VETJKRU/ref=sr_1_6?ie=UTF8&qid=1453231200&sr=8-6&keywords=cinch+straps

Thursday, January 14, 2016

January 14, 2016

Today, we designed a hinge for this prototype. One will be printed so that we can make further adjustments before printing two. We will begin exploring different material options, design shapes, and whether we will be doing an outside-the-shoe brace or one that fits inside the shoe. A band will need to be ordered so that the calf section will be secure, and we will need to figure out a method of securing the bottom section. The product's general design will be perfected before allowing increased motor function through adjustable tension.

Also, a second meeting will be scheduled with our City As Our Campus Mentor to discuss our prototype and future plans.

Also, a second meeting will be scheduled with our City As Our Campus Mentor to discuss our prototype and future plans.

We hope to order this cinch strap (12 inch). These can be used to secure the calf section and maybe the foot sole section as well. https://www.securecableties.com/12-inch-black-cinch-strap-5-pack

Wednesday, January 13, 2016

Tuesday, January 12, 2016

January 12, 2016

Today, we edited the CAD model for the calf section so that instead of a 180 degree rotation, it is a 195 degree rotation. This will hopefully allow the holes at the bottom to line up more parallel. We also edited the foot sole attachment so that the two pieces fit closer together. These will be printed again, and then we will design the attachment of the two pieces and the function that lifts the user's toes up.

Friday, January 8, 2016

January 8, 2016

The products that are being designed now for this issue of drop-foot restrict the client's foot and calf to 90 degrees. This inhibits them to walk completely naturally, and often, the individual actually has the strength to push off with their foot sole in order to propel themselves forward (this requires a greater than 90 degree angle). Our design will not restrict this movement, but will use an elastic adjustment system to push the individual's toes up (making the angle less than 90 degrees) after they have lifted their foot up in the process of walking.

Thursday, January 7, 2016

January 7, 2016

The second part of our brace (the design which goes outside of the shoe) has been printed and seems to fit nicely with the calf section. We will continue to make adjustments.

Wednesday, January 6, 2016

January 6, 2016

Today while designing the foot sole part of our brace, I came up with the idea to possibly be able to get rid of the sole that goes in the shoe altogether. The calf part of the brace can instead be attached to any shoe and still provide the user with the same assistance because now the shoe itself is acting as the sole that is attached to the rest of the brace. Also this way, the costs can be cut because the majority of the product is the one section which is 3D printed. We will explore this idea and most likely design two products, one with the sole that fits inside the shoe and one in which the shoe is used as the "sole" itself (this will require a semi-custom/adjustable attachment to work with different types of shoes/sizes which will need to be made out of durable material and a strap to secure the shoe). After we have concrete prototypes for each, we will begin exploring the actual functionality and how our elastic-adjustment will work.

-Naomi

-Naomi

|

| This will be printed |

Monday, January 4, 2016

January 4, 2016

We started off the first class of the new year creating an abstract for our AFO. We gave a general synopsis of the device including such knowledge as the prototyping process, the device's goal, and the future of our research/design process. The official abstract can be viewed in the Design Process tab or at this following link http://mobilitycures2016.blogspot.com/p/design-process.html.

Subscribe to:

Comments (Atom)